This story reminds us of the importance of quality. What were the lead time and cost drivers that allowed this part to be used? What was the role of inspection and test and lack of process controls? Did lack of supply chain planning drive poor decision-making?

How are these risks being addressed post Covid, or are they? When lead times are exponentially increasing and quality is more and more suspect, manufacturers need to be wary and adjust processes to address changing conditions. How are these problems being managed by OEMs, contract manufacturers and their suppliers?

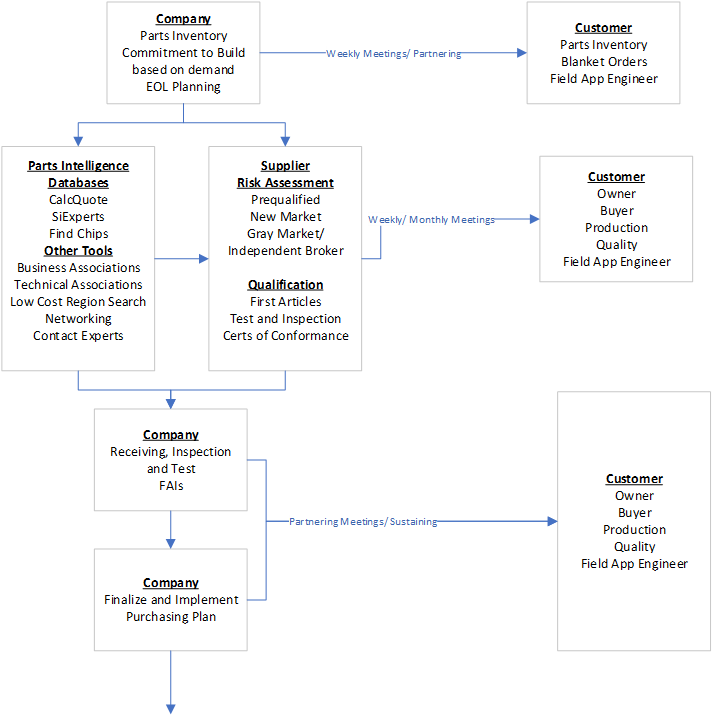

Controltek, Inc. Vancouver, WA implements a comprehensive supply chain risk assessment and purchasing process to address these risks. Two of my clients are benefiting from Controltek’s unique, robust systems. A detailed supplier qualification and selection process actuated on a parallel path with a parts requirements and availability process that minimizes costs, lead time, and quality issues. Working with their Customer as a Team, Controltek is successful in sustaining production and finished goods output in these difficult times. Controltek’s strategy and tactics, use of parts intelligence databases, and allocation of internal resources work to purchase “impossible to find” components with “impossible to get” lead times. Andy LaFrazia, President of Controltek, shared their approach, tools and processes.

Parts Availability and Purchasing

First, Controltek works closely with customers to understand the demand for and the critical items used to build their products. Upfront discussions about potential upside and downside to inventory volume are part of the conversation. It is critical to understand component lead times to properly plan supply chain purchases. Customer expectations for their product lifecycle and component purchases are also part of the conversation. With the shortening of electronic component lifecycles along with unplanned End-of-Life (EOL) notices, close communication and continuous monitoring is needed between the supplier and OEM or contract manufacturer. (These factors are best considered as part of the design process but are often addressed later or long after the product is released for manufacturing.)

Second, Controltek parts availability and purchasing process assesses lead time and cost for product sourcing. The primary goal is to have inventory and orders in place to support the Customer demands. (Lead time and cost assessment is best conducted during the product development stage where the sourcing is considered as part of the design process along with DFx – Design for Manufacturing, Test, Sustainability/Environment, Cost.)

Controltek recommends using blanket purchase orders from Customers with delivery flexibility. Controltek may hold a little extra inventory for the Customer, but this strategy can reduce risk and production delays significantly. Several parts intelligence databases are used to identify alternatives and crosses. If none can be found, Controltek evaluates cost benefit of a circuit board redesign. Since Controltek has internal Engineering Design resources, this evaluation is quick and cost-effective for their clients. Optimally, an acceptable alternative is found that does not require a design change. If a “drop-in” alternative is not available, Controltek looks for easy options such as using the same part but in a different package. Many times, the most cost-effective solution is where a simple PCBA layout update can solve the part challenge.

Certain regulated products may require risk analysis with additional documentation and/or testing (especially for medical or aerospace products) before a design change is implemented.

Parts Intelligence Databases

Contoltek starts with CalcuQuote. The entire Customer Bill of Materials (BOM) is uploaded into this application. CalcuQuote evaluates market availability, lead time, and cost if the part is available in the primary market. Using this tool, a quick view of pricing and problem parts (i.e., no stock with long lead times) provides an opportunity to prioritize actions related to procurement.

Silicon Experts (parts intelligence service) is also utilized. This application identifies component risk and provides insight into electronic component lifecycle status, multi-sourcing, available inventory, and predicted EOL. It also incorporates industrial standards and regulatory reporting requirements, data on which components are at risk for compliance issues. These compliance requirements include RoHS, REACH, TSCA, POP, Cal Prop 65, conflict minerals, etc. This is a web application with an annual subscription fee based on the number of components being monitored.

Findchips.com, a free service, is also used for parts intelligence. Findchips offers a single place to view up-to-date pricing and inventory from the world’s largest distributors. Alerts are set for inventory and pricing changes for a specific manufacturer part number to receive email notifications based on customized settings.

Controltek also uses other free services offered by electronic part distributors as well as other free web resources.

Supplier Risk Assessment

Controltek conducts a risk assessment based on specific Customer needs for certification (ISO, AS, etc.).

First, Controltek contacts their trusted franchised distributors. Franchised distributors (such Avnet, Arrow, Mouser, Digikey, etc.) are prequalified by Controltek for components they are franchised by OEMs to market and sell. These suppliers follow strict procedures to confirm quality and traceability of components. If components are not available from franchised distribution, ControlTek will work with independent broker/distributors (sometimes termed the ”gray market”) to acquire parts. When this occurs, written customer approval is required for every non-franchised part.

The distributors and brokers often have their own test and inspection laboratories used to qualify and certify part quality. Brokers require another level of due diligence. Some Customers are not allowed to buy from a broker without additional qualification, based on market sector and industrial standards requirements and government regulations.

Second, if the parts are not available or lead times are too far out through these sources, Controltek taps the gray market to find and qualify a supplier using the Electronic Resellers Association International (ERAI). ERAI maintains a database of known counterfeit suppliers and acts as an agent to stop counterfeit parts.

Controltek documents this risk assessment and gathers the supplier certs and qualification. For some market sectors additional databases are tapped, e.g., AS9102 registration status in the OASIS database.

OASIS is the Online Aerospace Supplier Information System®, a portal for all information related to Aerospace Quality Management System (AQMS) certifications and auditors. OASIS contains a list of suppliers who are certified/registered under the IAQG rules as compliant with the aerospace industrial standards (AS 9100 series).

If there is any question about the supplier or part, Controltek conducts or outsources detailed testing and inspection of samples and incoming parts, including solder, metallurgy analysis, X-ray, and functional tests.

For gray market suppliers, escrow is used to hold payments until parts are delivered and qualified.

Evaluation and Purchasing

From the assessments, Controltek develops a plan for purchase of the materials for each BOM and works with the Customer to implement the plan. Some Customers prefer to hold inventory, others to maintain inventory at Controltek. Blanket orders for materials only are used as the contract strategy to minimize costs with the Customer involved in determining specific purchasing requirements and actions.

Critical, expensive, and hard to get items with long lead items are prioritized for purchase, or alternatives or crosses identified and sourced. Controltek works with design teams to identify multiple manufacturers and the associated part numbers for as much of the BOM as possible. The plan is executed to ensure a consistent supply of parts and minimize costs and risks.

Based on current supply chain challenges and market, two (2)- to three (3)-year purchasing agreements and blanket orders are recommended for critical items. Controltek works with each Customer to plan for production based on parts availability projected 2-3 years out now that some components have nearly 2-year lead times. Note that regular surveillance of the entire BOM is needed since components with no problems today can have unexpected issues tomorrow.

Prioritizing Purchases with Suppliers

Several strategies are utilized to prioritize Controltek purchases with suppliers., including

Defense Rated Orders. –

The Defense Production Act (DPA) authorizes the President to require acceptance and preferential performance of contracts and orders deemed necessary or appropriate to promote the national defense. A rated order is a contract or order placed in support of a national defense program, pursuant to section 101(a) of the DPA. A rated order takes precedence over all unrated orders, when necessary to meet delivery dates specified in the rated order. If the Customer is manufacturing a finished good that is needed for military defense application, these orders take priority in the supplier’s delivery commitments. The supplier is required to prioritize that PO fulfillment over others.

One common strategy for components facing end-of-life is to make a large purchase to support the end product’s planned lifetime. This option is compared to the cost to make design changes and many times is the most cost effective. Requirements for proper storage of the components to limit age-related issues (typically oxidation that can cause soldering problems) is considered.

Conclusion and Next Steps

Is this process applicable only to Electronic Manufacturing Services and printed circuit board assemblies? No. The same process applies to metal, plastic and other components, materials and finished goods. These challenges and application of similar methods will be described in subsequent articles.

“Halfway through construction of its new headquarters in South Central Los Angeles, the U.S. Postal Service made a disturbing discovery. At least 20,000 of the nuts and bolts in the building were counterfeit.” 1987 Los Angeles Times

More recently the Johnson and Johnson and Stryker hip replacement recalls and class action lawsuits 10 years ago come to mind.

Learn more about how to evaluate your supply chain.

Contact Andy LaFrazia Andy@controltek.com or Debra Mervyn Debra@MervynGroup.com to learn more.