The Idaho Manufacturing Alliance hosted a Supply Chain Business Opportunities Conference March 14, 2023, Boise. The conference was well attended with a cross section of large and small businesses and service providers. I was invited to present on “Post Pandemic Procurement” strategies and tactics including risk management, supplier qualification and partnering, and procurement. These elements of a successful Supply Chain strategy seem simple and essential business best practices. Still many businesses small to large do not have or successfully implement these systems.

My sources were from personal experience and close business associates and manufacturers in the EMS/ PCBA, Aerospace, Medical Device, Metals. Bottom line, all industry sectors have been impacted by Covid and post supply chain ramifications. Lead times may be half what they were two years ago, but they are still at least twice what they were in 2019. Quality, too, has suffered.

On Time Delivery

Raw Material Availability

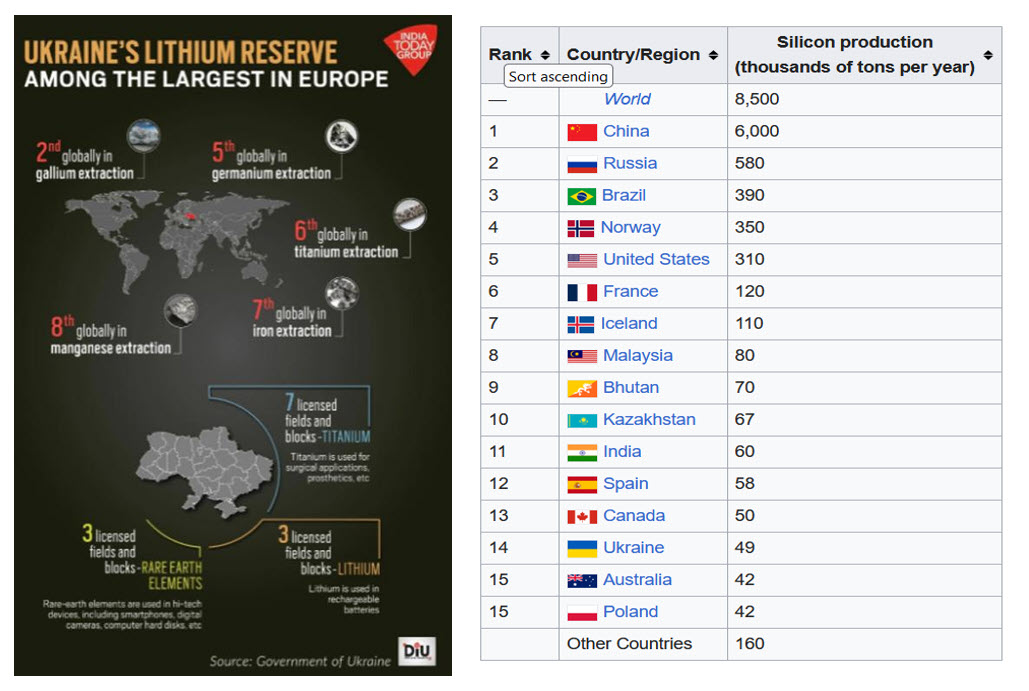

Due to geopolitical including war or threats thereof, raw material availability is now a bottleneck.

Mike Schindele – Axiom Electronics

“Impacts are global and across all commodities. Suppliers have problems purchasing raw materials due to geopolitical issues. Ukraine has unique gases and minerals that are no longer flowing. Silica to is not readily available. Delivery times are up to two years. Spotty improvements have been actualized, at best. Human resource shortages are another supply chain issue.” The Walgreens near Mike’s home is only open Monday through Friday 8am to 5pm due to staff shortages.

Introduction and Risk Management- Presentation: Part 1 of 3

Ten years ago, I was working with one of my clients on offshore (China) supplier quality and delivery problems. I conceived a notion of following the procurement and manufacturing value stream and applying Activity Based Cost Accounting “light” to quantify labor, direct and indirect costs associated with each activity, problem, and the remedies (solutions). I determined the true cost of goods sold, margins, and solutions. The client’s margins were eroded dropping from healthy to upside down. The solution to the margin erosion was clear. By holding the Chinese supplier responsible for quality, and helping them to do so, we were able to save $1 million the first year. The tools we used to identify and actualize these savings and improvements included Risk Management, Supplier Qualification and Purchasing tactics.

Shortly after, I was invited to speak on this method, I thought I developed. Headed out the door, a colleague called and informed me the Wall Street Journal had just released an article on this method.

Once Made in China: Jobs Trickle Back to U.S. Plants By JAMES R. HAGERTY Monday, May 21, 2012 As of 7:04 PM

This method was being used to Reshore products and lower risk by several U.S. OEMs.

Later I discovered this method had a name “Value Stream Cost Accounting” or “Lean Accounting”. More than 10 years later few organizations use this powerful tool.

Where to begin? Step 1- Risk Assessment and Management

Risk Assessment and Management

Now is the time to apply risk management to Suppliers and Purchasing.

Risk Management has been around so long there is an International Standard for it, ISO31010 (or ISO 13485 for Medical Devices). Numerous methods are recommended in these standards. The methods can be simple and effective or cumbersome and painful, or overkill. The easiest and most effective for Supply Chain is the hazards analysis.

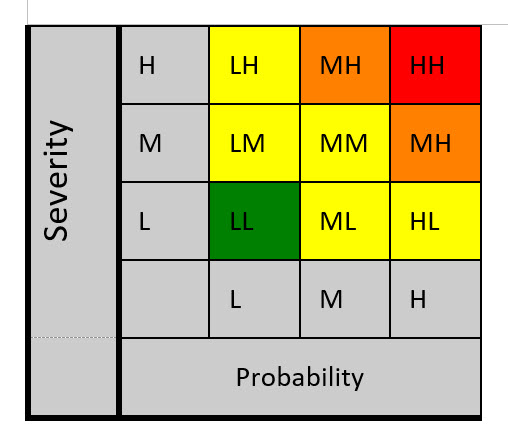

Hazards Analysis- Identify the hazard or hazardous situation and events for a certain activity, facility or system and its impact. Example. Low, Medium or High

Probability – Likelihood this risk will happen or has happened in the past.

• High – Happens frequently.

• Medium – It is 50/50 whether this will happen.

• Low – This will be unlikely to happen, but is possible.

Impact – Either financial, delivery or quality will be impacted if this risk happens.

• High – Impact may be stop production or cause impacts to quality and delivery.

• Medium – Impact may be significant enough to require change or adjust the schedule or other production factor.

• Low – Impact is small and can be accommodated by minor production change.

The key to success is involving a cross functional team in the assessment, with a good facilitator. The team should consist of employees involved directly with the process, who will speak the truth, and can provide effective solutions to problems. This is opposed to an individual or two who want to tell the president, owner, or board what they want to hear. “Good luck with that”, Jordan Peterson.

The team identifies the risks based on their experience. The organization decides when to act on the risk. Typically, the orange and red zone necessitate action. However, some organizations choose to act in the yellow MM zones, or document actions already taken to address risk.

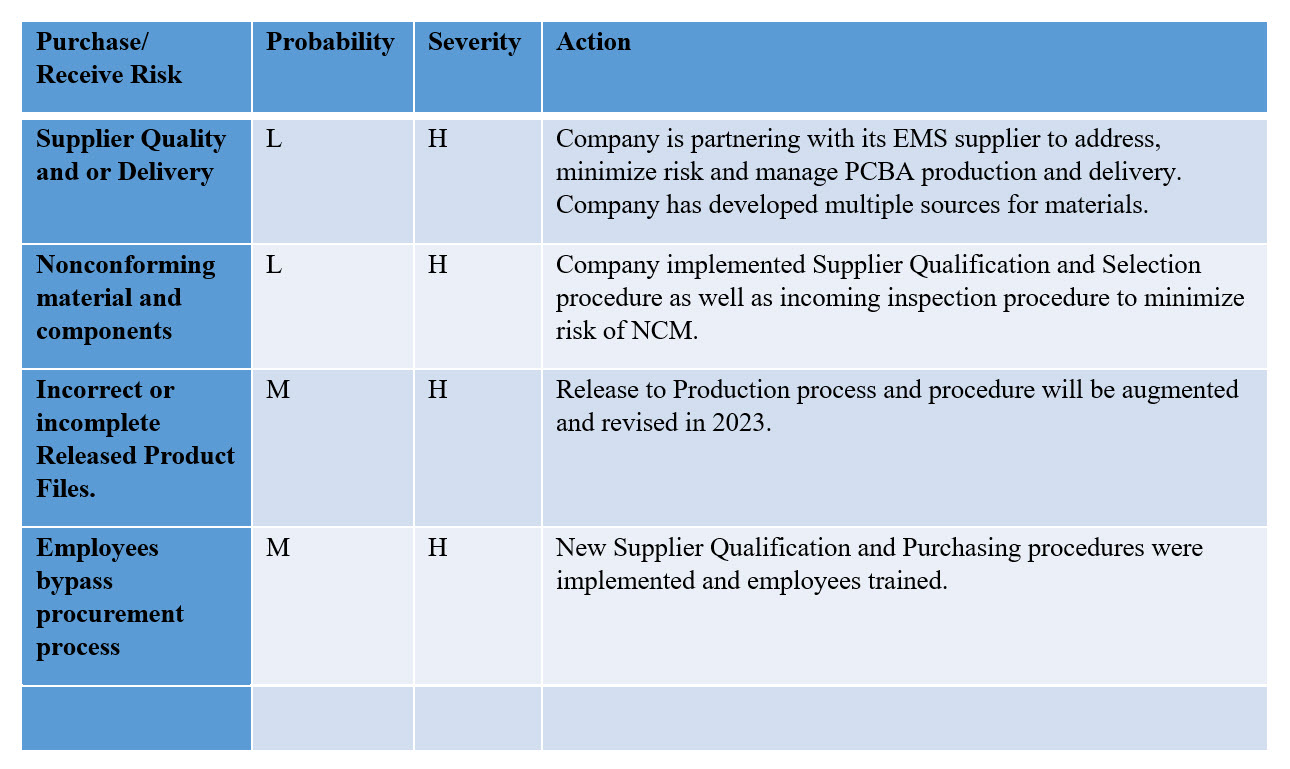

This example is a supply chain and purchasing assessment I led for a client in preparation for threats during and post Covid. The cross functional team consisted of the owner/ COO, office manager, production manager, purchasing, and engineering. Based on the assessment, they developed a successful tactical plan to address risk.

The next example (see Power Point presentation) is a template used by one of my clients for Supplier Risk Assessment.

Risk mitigation or reduction solutions are different for each company. Examples:

- EMS/ PCBA- This contract manufacturer evaluated their China Risks and moved to other low-cost countries after completing a value stream mapping and costing analysis for production in China.

- Metals Forming and Distributor- This organization evaluated geopolitical issues and risk of procurement from their most reliable and best supplier, a Russian Smelter. They are purchasing raw material from less reliable suppliers with poorer quality located in Canada, Mexico and India.

- Instrumentation for Nuclear, Aerospace, DoD- This company partnered with their primary PCBA subassembly supplier to outsource parts strategy and planning and procurement.

- Commercial- Implemented Supplier Qualification and Management program. They developed detailed PO requirements for quality and delivery. In addition, they requalified all suppliers and are qualifying secondary suppliers based on risk.

Keith Krach- Chairman and Co-Founder, Krach Institute for Tech Diplomacy at Purdue; former U.S. Under Secretary of State; 2022 Nobel Peace Prize Nominee, came across my Linked In feed when preparing this talk.

Contact Debra Mervyn Debra@MervynGroup.com to learn more.

Next Article- How to qualify, manage and partner with Suppliers.